Industry requirement

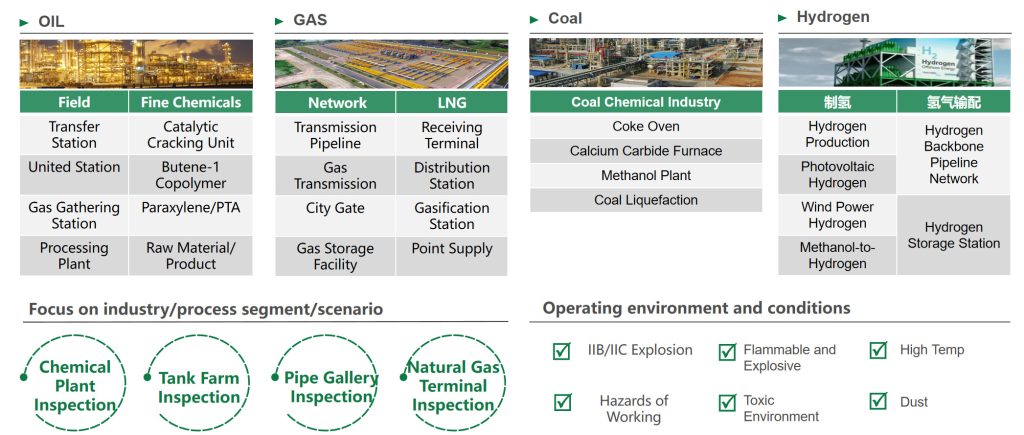

The oil and gas industry faces complex and ever-changing inspection challenges, particularly in critical areas such as chemical plants, tank farms/warehouses, multi-story elevated pipe corridors, and natural gas terminals. These scenarios often involve hazardous environments such as IIB/IIC explosion-proof zones, flammable and explosive atmospheres, high temperatures, hidden dangers of working at heights, toxic environments, and dust pollution. As a result, there is a pressing need for highly adaptable and safe robotic inspection solutions to automate and intelligently replace or assist manual inspections, enhancing efficiency, reducing personnel safety risks, and ensuring the safe and stable operation of oil and gas facilities.

Solution

Comprehensive Operation and Maintenance Solution for Oil and Gas Chemical Plants

— Multi-form and Cross-regional Intelligent Joint Inspection

The comprehensive inspection of oil and gas chemical plants is composed of three parts: mobile explosion-proof robots, fixed AI explosion-proof pan-tilt-zoom cameras, and the Industrial Internet Platform. Through the coordinated monitoring of multi-form devices, a new mode of comprehensive and full-coverage hardware-software integration for oil and gas chemical plants is achieved.

- The explosion-proof wheeled inspection robot adopts four-wheel drive and can meet the requirements of close-range, non-contact inspection in outdoor ground scenarios under all-weather and special operating environments.

- The Industrial Internet Platform system provides a three-dimensional and highly efficient safeguard mode for oil and gas chemical plants through high-frequency scanning of AI-powered pole-mounted pan-tilt-zoom cameras, combined with detailed inspections by the explosion-proof wheeled robots on the ground.

- The fixed AI explosion-proof pan-tilt-zoom camera is primarily used for fixed monitoring in complex environments such as narrow spaces and specific high positions where mobile inspection robots cannot reach.

- The fixed AI explosion-proof pan-tilt-zoom camera is installed at high positions in the plant, undertaking high-altitude monitoring tasks. It possesses ppm-level high sensitivity, covering a radius of up to 100 meters, and multiple independent cameras can operate simultaneously.

- It can be configured with key equipment, area focus, and locked scanning monitoring modes along pipelines. When abnormalities are detected, the explosion-proof inspection robot can be activated for further detection and confirmation.

- It coordinates the control of cameras and robots within the management area, providing analysis and early warning based on real-time inspection data and trends. It also exhibits good integration with the plant’s production scheduling system and operation and maintenance management system.